This is to explain the various gearing on our different heads.

Calculating Pulses/µL for the 27:1 EMO and VOL

The EMO and VOL heads each have:

A. A 1.8° stepping motor, running in 1/16th microstep mode;

B. A 27:1 planetary gear;

C. A 1:1 drive screw coupling;

D. A drive screw with a pitch of 18 threads per inch, or 1.411 thread per mm;

E. And a reservoir with a 17 mm diameter, or 227 mm2 cross section.

The table below explains how a certain number of pulses (or microsteps) on the motor will generate a certain volume displacement in the reservoir - the pulses/µL number that we need to control the material flow.

Flow Calculations for the 27:1 EMO and VOL Heads

| Component

|

Motor

|

Gearing

|

Coupling

|

Drive Screw

|

Reservoir

|

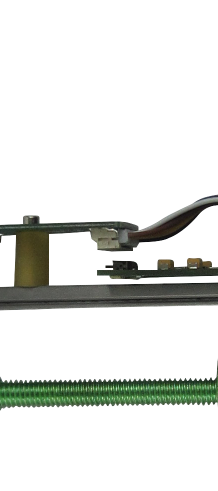

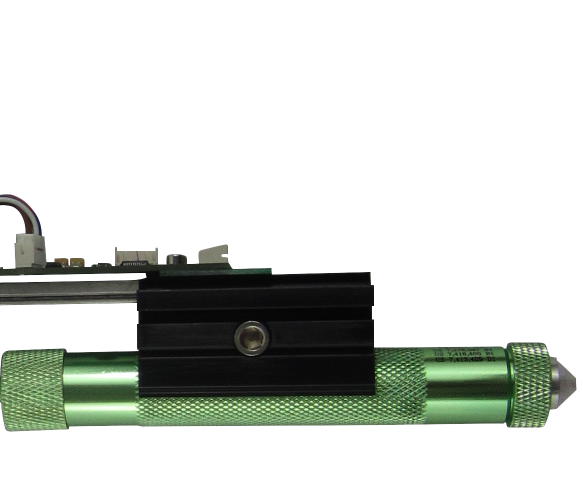

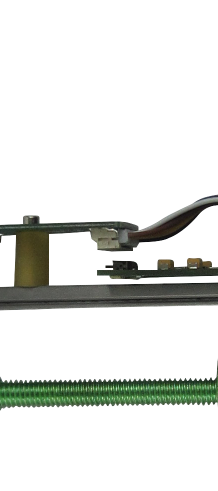

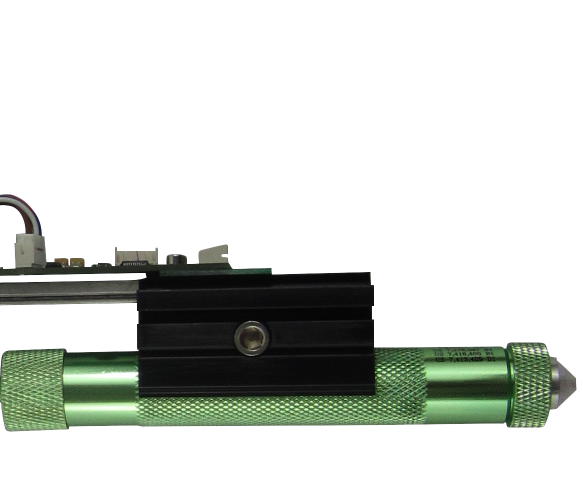

| Image

|

|

|

|

|

|

| Details

|

This is a 1.8° stepping motor,

so 200 full steps = 1 revolution.

1 pulse is a 1/16th microstep,

so 3200 pulses = 1 motor rev.

|

27:1 planetary gear,

so 27 motor revs

= 1 output rev.

|

1:1 direct coupling,

so no change

is introduced.

|

The drive screw has a pitch

of 18 threads per inch, or

1.411 mm linear travel

per revolution.

|

The reservoir has a diameter of 17 mm,

so the cross sectional area is 227 mm2.

Therefore, each revolution of the drive screw

displaces 1.411 x 227 or 317.8 mm3 (or 317.8 µL) of volume.

|

1 Rev

Calc.

|

86,400 pulses =

27 motor revs...

|

= 1 output rev...

|

= 1 screw rev...

|

= 1.411 mm linear advance...

|

= 317.8 µL displacement.

|

| And so:

|

86,400 pulses = 317.8 µL, or 271.9 pulses/µL

|