Difference between revisions of "Pulses per Microliter"

(→The 27:1 EMO and VOL) |

(→The 100:1 EMO-XT, KR2, and TAM) |

||

| Line 57: | Line 57: | ||

== The 100:1 EMO-XT, KR2, and TAM == | == The 100:1 EMO-XT, KR2, and TAM == | ||

| − | The EMO and | + | The EMO-XT, KR2, and TAM heads each have: |

* A 1.8° stepping motor; | * A 1.8° stepping motor; | ||

** Running in 1/16th microstep mode; | ** Running in 1/16th microstep mode; | ||

| − | * A | + | * A 1001 planetary gear; |

* A 1:1 drive screw coupling; | * A 1:1 drive screw coupling; | ||

| − | * A drive screw with a pitch of | + | * A drive screw with a pitch of 1 thread per mm; |

* And a reservoir with a 17 mm diameter, or 227 mm<sup>2</sup> cross section. | * And a reservoir with a 17 mm diameter, or 227 mm<sup>2</sup> cross section. | ||

| Line 69: | Line 69: | ||

{| border="1" class="wikitable" style="text-align: center;" cellpadding="0" | {| border="1" class="wikitable" style="text-align: center;" cellpadding="0" | ||

| − | |+ Flow Calculations for the | + | |+ Flow Calculations for the 100:1 EMO-XT, KR2, and TAM Heads |

|- | |- | ||

! Component | ! Component | ||

Revision as of 17:33, 27 July 2020

This page will explain the various gearing on our different heads, and how we determine a baseline pulses per microliter value.

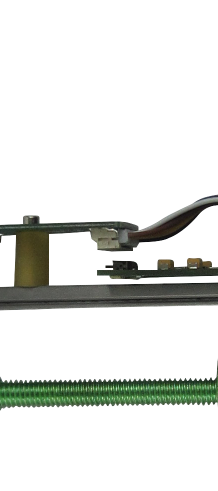

The 27:1 EMO and VOL

The EMO and VOL heads each have:

- A 1.8° stepping motor;

- Running in 1/16th microstep mode;

- A 27:1 planetary gear;

- A 1:1 drive screw coupling;

- A drive screw with a pitch of 18 threads per inch, or 1.411 thread per mm;

- And a reservoir with a 17 mm diameter, or 227 mm2 cross section.

The table below explains how a certain number of pulses (or microsteps) on the motor will generate a certain volume displacement in the reservoir - the pulses/µL (or pulses/mm3) number that we need to control the material advance or displacement. Note that factors like viscosity, compressibility, and nozzle characteristics will introduce some delay from the time of displacement to the time of actual extrusion.

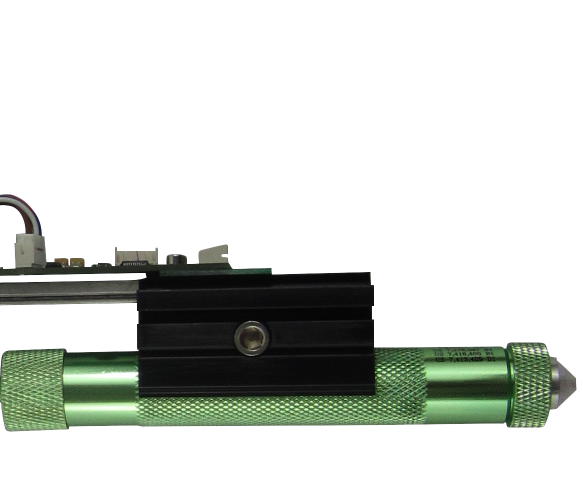

The 100:1 EMO-XT, KR2, and TAM

The EMO-XT, KR2, and TAM heads each have:

- A 1.8° stepping motor;

- Running in 1/16th microstep mode;

- A 1001 planetary gear;

- A 1:1 drive screw coupling;

- A drive screw with a pitch of 1 thread per mm;

- And a reservoir with a 17 mm diameter, or 227 mm2 cross section.

The table below explains how a certain number of pulses (or microsteps) on the motor will generate a certain volume displacement in the reservoir - the pulses/µL (or pulses/mm3) number that we need to control the material advance or displacement. Note that factors like viscosity, compressibility, and nozzle characteristics will introduce some delay from the time of displacement to the time of actual extrusion.