Difference between revisions of "Main Page"

(→Engines and Systems) |

(→Printers) |

||

| Line 15: | Line 15: | ||

=Printers= | =Printers= | ||

| − | As of Jan, 2016, Hyrel Printers are available in two models: [[Engines]] and [[Systems]]. | + | As of Jan, 2016, Hyrel Printers are available in two models: [[Engines]] and [[Systems]]. The Next Big Thing should be announced this quarter. |

| − | ==Engines | + | ==Engines== |

| − | [[Engines]] are open-air models. Detailed information is on the [[Engines | + | [[Engines]] are open-air models. Detailed information is on the [[Engines]] page. |

| − | + | [[File:ENG_small.jpg]] | |

| − | [[File:S30M_small.jpg | + | Above: '''The Engine''' |

| + | |||

| + | ==Systems== | ||

| + | |||

| + | [[Systems]] are enclosed models. Detailed information is on the [[Systems]] page. | ||

| + | |||

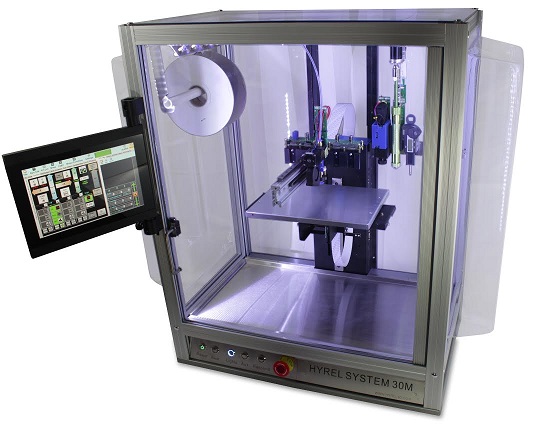

| + | [[File:S30M_small.jpg]] | ||

Above: '''The System 30M''' | Above: '''The System 30M''' | ||

Revision as of 17:46, 1 February 2016

Welcome to Hyrel!

With literally thousands of materials to print on the Hyrel Printer, we have broken down the list of materials into logical groups based on their printing temperature and type of head used to print them.

If you are planning on using the heads which photoinitiate crosslinking, make sure you specify the correct wavelength of LED for your material.

A standard material printing data sheet has been created for materials that have been internally tested; you can access this data by clicking on the material name below.

Always be sure of what material you are using, and what will be off-gassed.

Printers

As of Jan, 2016, Hyrel Printers are available in two models: Engines and Systems. The Next Big Thing should be announced this quarter.

Engines

Engines are open-air models. Detailed information is on the Engines page.

Above: The Engine

Systems

Systems are enclosed models. Detailed information is on the Systems page.

Above: The System 30M

The Next Big Thing

Information not yet available. :)

The Cold Flow Process

Cold Flow is our term for fluid or emulsified (non-filament-based) materials which are deposited at room temperature, with or without UV Crosslinking.

Materials for Cold Flow

The following materials can be printed from Cold Flow heads. Note that more viscous materials may not be suitable for plastic syringes or smaller luer tips.

- 3P Quick Cure Clay

- Adhesives

- Clay, Generic

- Epoxy, Two-part

- Fimo

- Glue

- Kato

- Metal Clay, including Precious Metal Clay (PMC)

- Modeling Clay

- PEG PolyEthylene Glycol

- Porcelain

- Plasticine

- Play-Doh

- Resins

- RTV Silicone

- Sculpey

- Sugru

Heads for Cold Flow

The following table compares the properties of the various Cold Flow heads:

| Head | Container | Capacity | Nozzle | UV Crosslinking |

|---|---|---|---|---|

| EMO-25 | Aluminum | 25cc | 1.5mm, 2.0mm, Luer | No |

| COD-25 | Aluminum | 25cc | Luer | Yes |

| SDS-5 | Syringe | 05cc | Luer | No |

| CSD-5 | Syringe | 05cc | Luer | Yes |

| SDS-10 | Syringe | 10cc | Luer | No |

| CSD-10 | Syringe | 10cc | Luer | Yes |

| SDS-30 | Syringe | 30cc | Luer | No |

| CSD-30 | Syringe | 30cc | Luer | Yes |

| SDS-60 | Syringe | 60cc | Luer | No |

| CSD-60 | Syringe | 60cc | Luer | Yes |

Research Papers Citing Hyrel Cold Flow

- Bioactive Nanoengineered Hydrogels for Bone Tissue Engineering: A Growth-Factor-Free Approach in The American Chemical Society's ACS Nano

- Design and Fabrication of 3D Printed Scaffolds with a Mechanical Strength Comparable to Cortical Bone to Repair Large Bone Defects in Nature.com's Scientific Reports

The Warm Flow Process

Warm Flow is our term for fluid or emulsified (non-filament-based) materials which are deposited at up to 150°C, with or without UV Crosslinking, depending on the head.

PCL and other medium temperature material can be printed directly from Pellets the size of small peas. If you pulverize or powder your polymer, it is possible to pre-mix the material dry and test different alloys of plastics.

Materials for Warm Flow

The following materials can be printed from Warm Flow heads. Note that more viscous materials may not be suitable for plastic syringes or smaller luer tips, or may print more easily at higher temperatures.

Heads for Warm Flow

The following table compares the properties of the various Warm Flow heads:

| Head | Max Temp | Container | Capacity | Nozzle | UV Crosslinking |

|---|---|---|---|---|---|

| VOL-25 | 100°C | Aluminum | 25cc | 1.5mm, 2.0mm, Luer | No |

| VCD-25 | 100°C | Aluminum | 25cc | Luer | Yes |

| KRA-15 | 150°C | Stainless | 15cc | 1.5mm, 2mm, Luer | No |

| KCD-15 | 150°C | Stainless | 15cc | Luer | Yes |

The Hot Flow Process

Hot Flow is our term for filament-based materials which are deposited at up to 450°C, depending on the head. As of January, 2016, our Hot Flow heads are only for 1.75mm filaments.

Materials for Hot Flow

The following materials can be printed from Hot Flow heads. Note that depending on the characteristics of your material, one head will be a better match than the others. See the "Recommended For" column in the table below.

- ABS, Acrylonitrile Butadiene Styrene

- BendLay

- FilaFlex

- Flex45

- LayBrick

- LayWood

- NinjaFlex

- Nylon

- PC, PolyCarbonate

- PEEK, PolyEther Ether Ketone

- PET, PolyEthylene Terephthalate

- PETG, PolyEthylene Terephthalate Glycol-modified

- PLA, PolyLactic Acid

- PlastInk Rubber

- PP, PolyPropylene

- PVA, PolyVinyl Alcohol

- T-Glase

Heads for Hot Flow

The following table compares the properties of the various Hot Flow heads, including which heads are recommended for which materials. The MK1 heads drive matieral from one side, with a spring-loaded bearing system to maintain pressure and positioning. The MK2 heads drive the material from both sides, and are designed for more flexible filaments.

| Head | Min Temp | Max Temp | Filament Type | Nozzle | Recommended For |

|---|---|---|---|---|---|

| MK1-250 | 150°C | 250°C | Standard | .35mm, .50mm, .75mm, 1.0mm | ABS, LayBrick, LayWood, Nylon PC, PET, PETG, PETT, PLA, PP, PVA, T-Glase |

| MK2-250 | 150°C | 250°C | Flexible | .35mm, .50mm, .75mm, 1.0mm | BendLay, FilaFlex, Flex45, NinjaFlex, PlastInk Rubber |

| MK1-450 | 250°C | 450°C | Engineering | .50mm | PC, PEEK |

Research Papers Citing Hyrel Hot Flow

- Demonstration and Characterization of Fully 3D-printed RF Structures, The Institute of Electrical and Electronics Engineers, Incorporated (IEEE)

- Infill Dependent 3D-Printed Material Based on NinjaFlex Filament for Antenna Applications, The Institute of Electrical and Electronics Engineers, Incorporated (IEEE)

- A Novel Strain Sensor Based on 3D Printing Technology and 3D Antenna Design, The Institute of Electrical and Electronics Engineers, Incorporated (IEEE)

- A Novel 3-D Printed Loop Antenna Using Flexible NinjaFlex Material for Wearable and IoT Applications, The Institute of Electrical and Electronics Engineers, Incorporated (IEEE)

- RF Characterization of 3D Printed Flexible Materials - NinjaFlex Filaments, The European Microwave Association (EuMA)

Lasers

Hot-swappable Lasers are available in the following configurations:

- The LA5-808 is 5W at 808nm, and due to its wavelength, it is best suited for darker material.

- The LA6-450 is 6W at 450nm, and performs well on opaque material of any color.

The Reflectivity and Transparency or Translucency of your material will have a great impact on the effectiveness of the laser. Safety glasses are included with each laser.

Spindle Tools

Intended for light drilling and routing operations (especially circuit board work), the ST1 provides between 500 and 5000 RMP (depending on load) to a 1/8" chuck. Our Repetrel software can process Gerber and DRL files for the Spindle Tool and/or the Lasers.

Other Heads

The following accessories each take up a tool position while performing more passive functions:

- The Inspector microscope provides magnification.

- The Quiet Storm fan provides additional cooling.

- The Digitram, provided with every printer, is used to level the build surface.

Non-Head Accessories

The following non-head accessories are also available:

- The Feed Chamber Cooling Fan mounts on Hot Flow heads to provide additional cooling to the feed chamber. This is desirable with low temperature filaments like PLA.

- The Printer Support Kit is included with every printer, and includes a build plate, blue tape, and a variety of handy tools like tweezers, razors, and a spatula.

- The Software Developer's Kit provides hardware, software, and the source code for developing your own firmware for your own compatible heads.

- The Luer Tip Kit provides an EMO to Luer adapter and a variety of luer lock needles.

- The Syringe Kit provides syringes in quantity.

- The Drill Bit Kit provides an assortment of drilling bits and end mills for the Spindle Tool.

- The Filament Kit provides...